Optimized Drying, Coating & Granulation

Ensure that even the heaviest materials have proper lift to fluidize and process efficiently. Whether you need solid dosage technology for R&D, pilot, or production applications, Fluid Air is the answer for more viable end products that perform.

Fluid Air fluid beds are recognized in the industry as a leader in air-moving technology using the highest-pressure, highest-flow process blowers. Variable frequency drive assures ideal horsepower for perfect airflow, while design flexibility means you can count on peak performance for fluid bed drying, granulation, and coating.

Robust MAGNACOATER® Wurster coaters feature even air distribution, extensive adjustability, superior nozzle design, and self-monitoring systems. What's more, these and our MAGNAFLO® fluid bed dryers and granulators can be fully customized to deliver superior performance across a wide range of solid dosage processing applications.

Model 0002–0010

Laboratory-scale units provide effective drying, coating or granulation for small batches.

MODEL 0002 - MODEL 0010 FLUID BED SPECIFICATIONS

MODEL 0002 - MODEL 0010 FLUID BED SPECIFICATIONS |

|||||||||

| 0002 | 0005 | 0010 | |||||||

| Standard Bowl Vol. (L) | 2.0 | 13 | 20 | ||||||

| Max Granulating Capacity (L) | 2 | 5 | 10 | ||||||

| Max Coating Capacity (L) | 1.8 | 6 | 10 | ||||||

| Extended Bowl Vol. (L) | * | * | * | ||||||

| Reduced Vol. Bowls (L) | 0.5 | 2 | 2, 5 | ||||||

| System Height (in/mm) | 72/1829 | 74/1880 | 80/2032 | ||||||

| System Width (in/mm) | 32/813 | 76/1930 | 78/1981 | ||||||

*Standard construction of these bowls may allow for extra drying/granulating/coating capacity depending on the product. Contact factory for details.

Model 0020–0120

Midsized systems offer a wide range of options for processing larger batches intended for clinical trial or small-scale production.

Model 0300–1200

Large scale fluid bed systems for processing of very large batches (up to 1200 Liters).

FLUID BED SPECIFICATIONS |

|||||||||

| 0020 | 0050 | 0120 | 0300 | 0500 | 0800 | 1000 | 1200 | ||

| Standard Bowl Vol. (L) | 46 | 57 | 148 | 346 | 617 | 967 | 1205 | 1437 | |

| Max Granulating Capacity (L) | 34 | 51 | 133 | 311 | 555 | 870 | 1084 | 1293 | |

| Max Coating Capacity (L) | 31 | 46 | 124 | 193 | 477 | 720 | n/a | n/a | |

| Extended Bowl Vol. (L) | n/a | 72 | 207 | 482 | 860 | 1346 | 1645 | 1961 | |

| Reduced Vol. Bowls (L) | 5, 10 | 5, 46 | 46, 57, 72, 97 | 148 | 346, 148 | n/a | n/a | n/a | |

| System Height (in/mm) | 1/2667 | 130/3302 | 138/3505 | 160/4064 | 148/3670 | 147/4420 | 185/4699 | 192/4877 | |

| System Width (in/mm) | 36/1981 | 48/1220 | 46/1168 | 72/1829 | 84/2134 | 96/2538 | 105/2667 | 114/2896 | |

Simplify Start-Up to Scale-Up

Streamlined Scale-up

Fluid Air fluid bed systems are designed with consistent critical factors for easy transitions. From the midsized Model 50 to our largest available units, each system operates with nearly identical bed depths, air velocities, and air ratios to greatly simplify scale-up from one system to the next.

Faster Granulation

The conical expansion chamber shape reduces the velocity of the air in the filter chamber by 50%. In addition to decreasing the total height of the chamber, this helps keep smaller particles out of the upper filter region and below the spray nozzles.

Quick, Cost-Effective Deployment

The industry's first prepackaged, factory-built inlet and exhaust systems significantly cut on-site construction costs. The modular design means the system can be quickly set in place and brought into service.

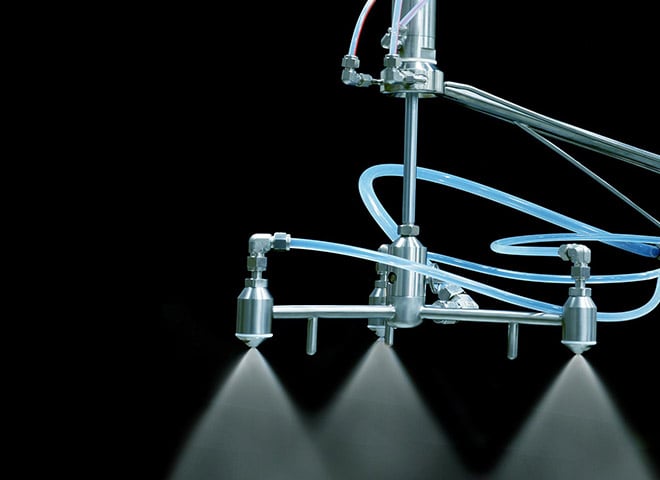

Efficient Top-Spray Liquid Delivery

A smart, top-spray arrangement assures even bed coverage with no side-wall wetting. In multinozzle granulation systems, nozzles are spaced out in a chandelier pattern and pointed straight down at the bed. Every nozzle has its own pump, assuring consistent, identical flow to each one. This results in higher operating efficiency and more uniform coverage of the fluidized bed.

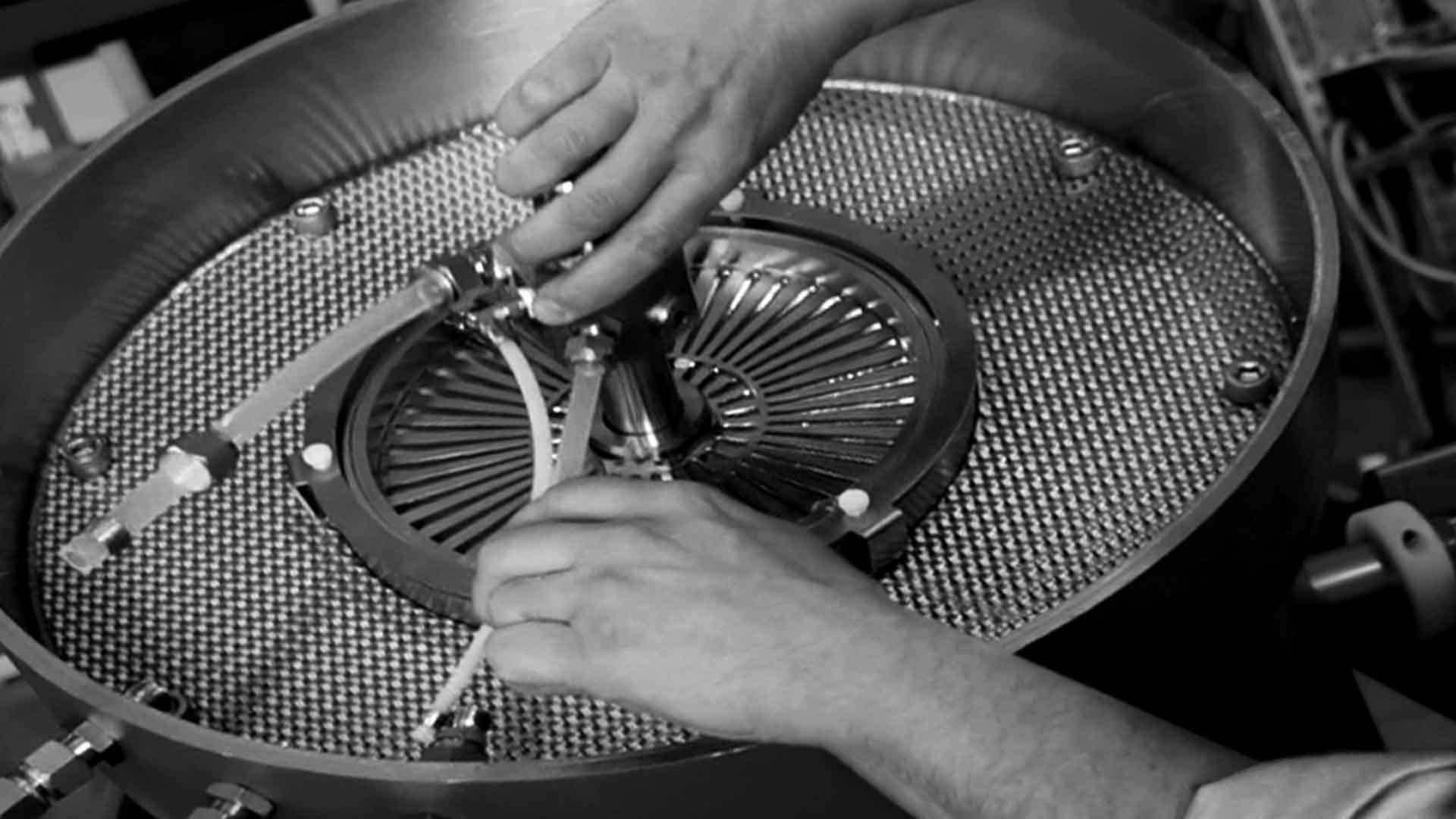

Spiraflo Bed Plate

A unique design assures uniform distribution of air across the bed plate, eliminating channeling and nonuniform fluidization patterns. The plate is constructed of sturdy, heavy-gauge stainless steel to resist fraying and breakage, and to allow a variety of tools to be used in product removal and cleanup.

High-Yield Process Filtration

Full-length filter bags provide the highest air-to-cloth ratio in the industry, which prevents side-wall buildup during drying and granulating and leads to higher batch yields. Choose from standard filter bags, cartridges, or a combination of cartridges within filters to customize for your applications. Each option features Fluid Air patented pulse filter cleaning technology.

- Filter bags—Extending the full height of the expansion chamber, these one-piece bags protect the stainless steel walls from product exposure. This helps prevent product accumulation, lowers operating temperatures, increases yields, and reduces cleanup time.

- Cartridge filters—Installed in the upper portion of the expansion chamber, cartridges are automatically pulsed clean, permitting continuous fluidization.

- Bag-and-cartridge combination—Achieve the benefits of each filter system, including automatic pulse cleaning and constant fluidization, plus higher yields and streamlined cleanup.

Flared Partitions

A multipartition air balancing system, located prior to the distributor plate assembly, balances the air flow going to each coating zone for uniform fluidization.

The Fluid Air flared bottom partition design incorporates a standard upper diameter and a larger bottom diameter. The larger, flared bottom forces the product to travel farther before reaching the spray nozzle. This longer distance ensures that the product is fluidized before it reaches the spray nozzle, so you can operate at higher spray rates.

.png?h=75&mh=150&w=358&hash=36844D2DB3DBD3A749E8E7C5AF4A49AA)