Case Study

Improving Probiotic Processing with Electrostatic Spray Drying Technology

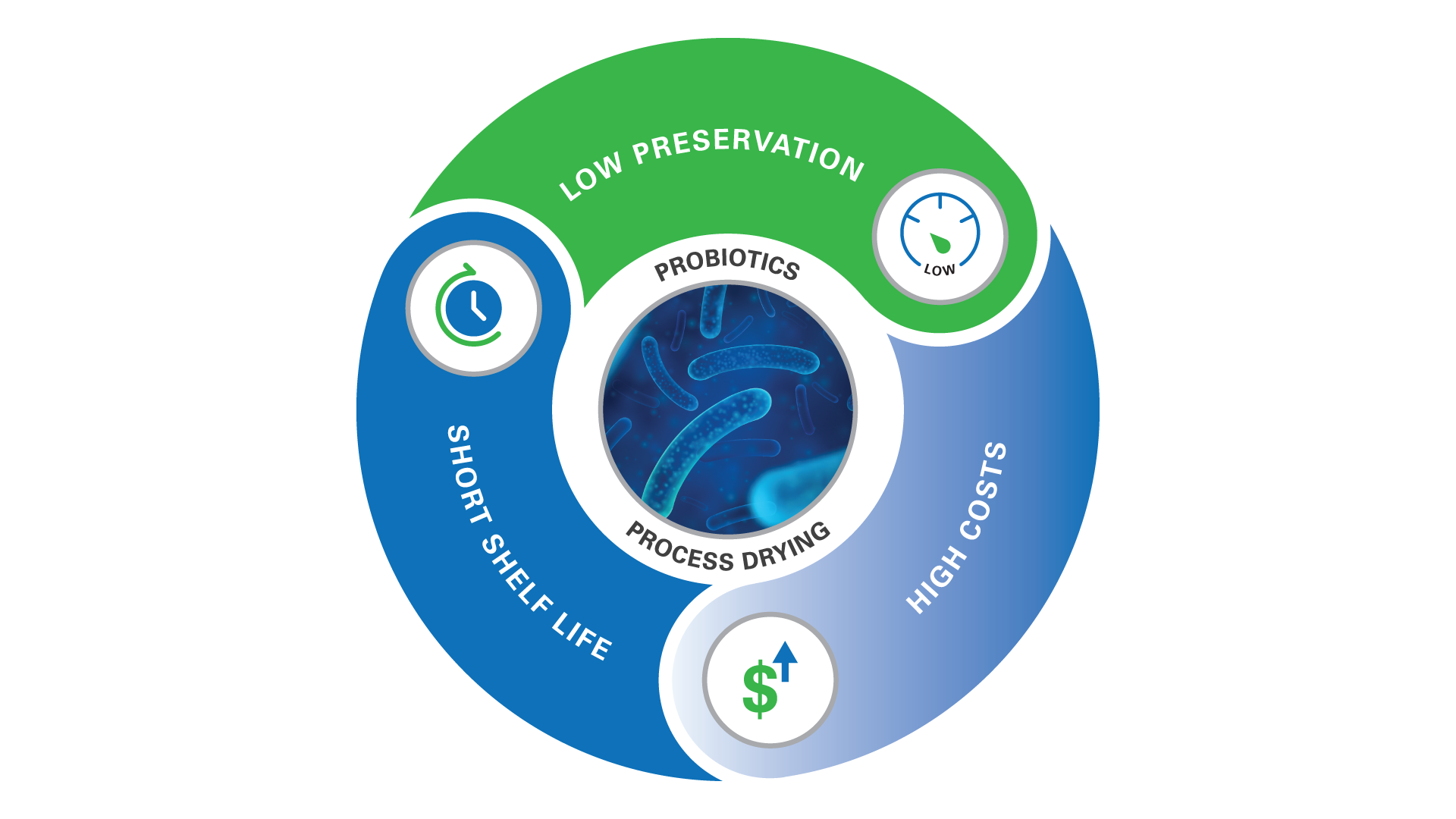

Challenges with Conventional Dryer Process

Probiotics, like the widely used Lactobacillus plantarum, are often dried to enhance stable shelf-life. Tests of Lactobacillus plantarum revealed that temperature and water activity were critical factors for probiotic survival during storage.

- Traditional spray drying causes inactivation of micro-organisms, due to the thermal and dehydration inactivation.

- Freeze drying can also damage biological systems, primarily because of the change in the physical state of membrane lipids or the change in the structure of sensitive proteins. Freeze drying is also time-consuming and energy intensive.

Common strategies employed to overcome these issues and optimize probiotic drying include:

- Inducing bacterial stress adaptation to enhance cellular intrinsic tolerance

- Applying protective agents to minimize cell damage during process

- Optimizing these conventional processes to moderate the harsh conditions

Download the Fluid Air Case Study for improving Probiotic Processing with Electrostatic Spray Drying Technology

Fluid Air provides custom, efficient and effective Solid Dosage Processing equipment and systems that can meet the most challenging powder modification and creation application. Dedicated to exceeding our customer's expectations in the design, realization operation and service of our products while conserving energy and the environment.

Download the data sheet to learn all about our Electrostatic Spray Drying Technology

.png?h=75&mh=150&w=358&hash=827BCD6F9E85DDA83A56BF1400B7043B)