Revitalize Your Tablet Coating Technology

Improve coating performance without replacing your current tablet coater or coating pan. Instead, upgrade only the core components of your existing equipment—the Fluid Air TABCOATER® system is a flexible answer for getting superior results out of aging technology.

Better Coating Results

Patent-Pending Performance

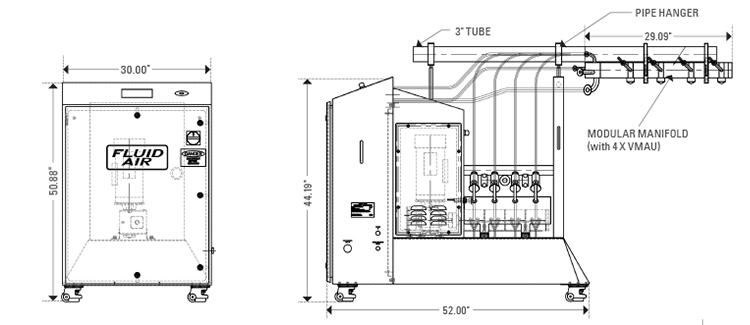

A specially designed, patent-pending air atomizing manifold upgrades your existing equipment to deliver high-performance spraying results. Each manifold incorporates four or more individually fed, recirculating VMAU spray nozzles, allowing the coating solution to flow continuously for consistently superior results.

Uniform, Clog-Free Spraying

Unlike traditional nozzles, TABCOATER recirculating nozzles keep solids from dropping out of suspension and temperature-sensitive solutions from hardening if liquid stops flowing or the flow rate is too low. This advance prevents uneven coating, nozzle clogging, and blockages, as the solution continues to recirculate even when the shut-off/cleanout needles are extended.

Streamlined Connection Hub

Because the liquid recirculation return is housed inside the nozzle body and ported through the manifold, fewer connections are required. This eliminates the need for multiple liquid and air lines to each nozzle, greatly simplifying setup, cleaning, and changeover.

54000 Modular Air Atomizing Manifold

Anti-bearding nozzles, patent-pending internal recirculating guns, a shut-off valve that keeps liquid moving and reduces build-up, and a mounting design that prevents tablet entrapment add up to exceptional results and streamlined operations. Fluid Air designs and fabricates manifold systems to your precise specifications.

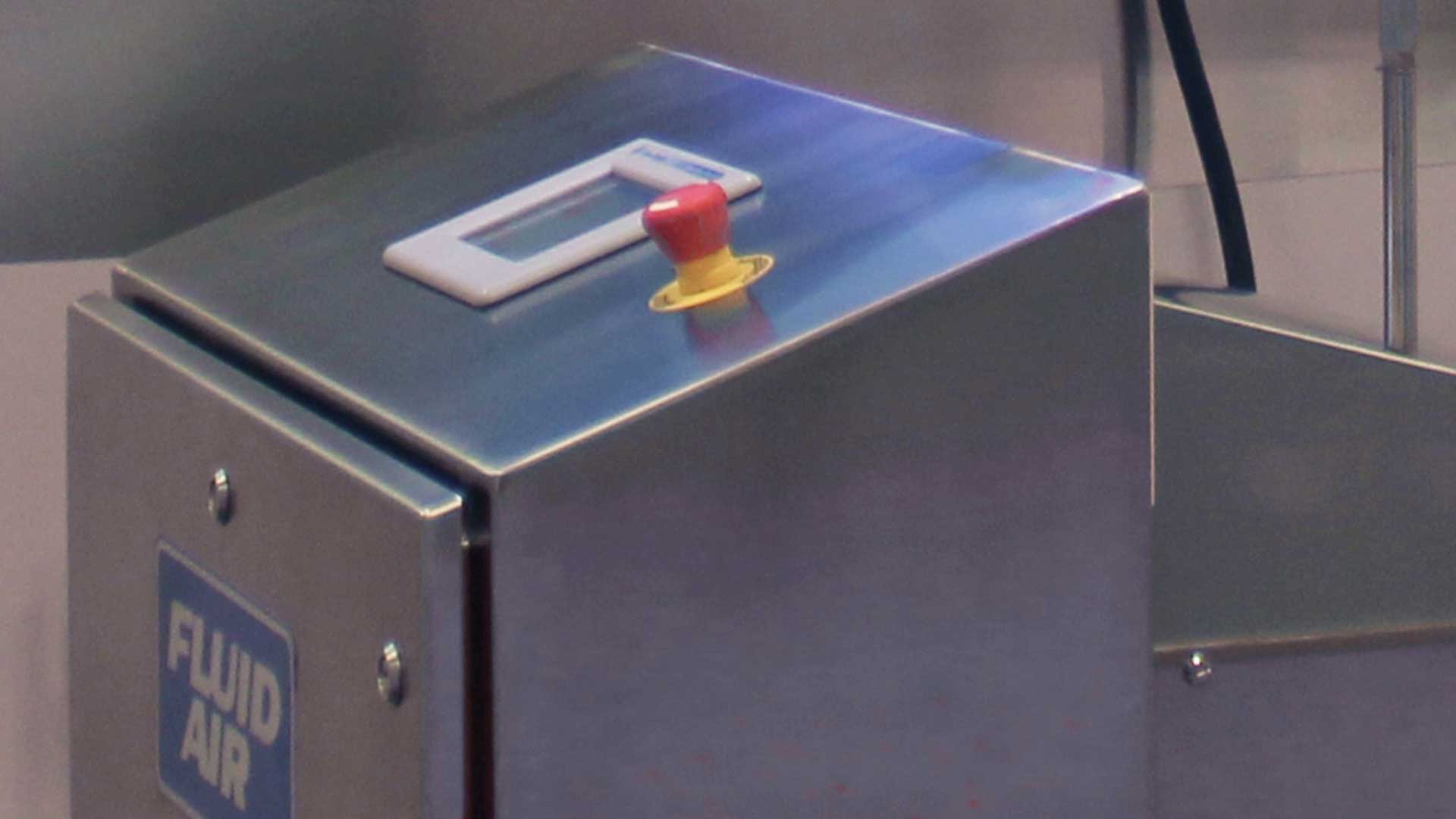

Batch Architect™ Process Controls

Automate for consistently optimal results. The Batch Architect platform features a custom PLC and touch screen that allow operators to easily automate the liquid delivery skid or entire pan operation with phase- or recipe-based controls. Includes optional 21 CFR Part 11 compliant data logging and security.

Customized Fluid Delivery Skids

The TABCOATER liquid delivery skid is designed to reduce costly trial and error. Operated manually or automated, the system features closed-loop solution delivery metering using loss-in-weight, mass flow sensing, and totalizing, as well as precise, low-pulsation peristaltic pumps that eliminate dead-leg liquid distribution.

Customize to Support Your Products

A variety of thoughtful options are available:

- Custom nozzle manifold configurations and support

- Manual, push-button, stand-alone liquid delivery solutions

- Automatic Batch Architect stand-alone liquid delivery systems

- Manual or automatic liquid delivery systems that interface with existing controls

- Full coating pan automation using Batch Architect Pro™ control systems

.png?h=75&mh=150&w=358&hash=36844D2DB3DBD3A749E8E7C5AF4A49AA)